Choosing the right membrane filter press manufacturer is important to ensure that you get a high-quality product that meets your specific filtration needs.

Here are some factors to consider when choosing a membrane filter press manufacturer:

Experience and Reputation: Look for a manufacturer with a good reputation and years of experience in the industry. They should have a track record of producing high-quality membrane filter presses and providing excellent customer service.

Quality Control: The manufacturer should have a rigorous quality control process to ensure that their products meet industry standards and customer specifications. They should use high-quality materials and employ skilled workers to manufacture their filter presses.

Customization Options: Your filtration needs may be unique, so it’s important to choose a manufacturer that offers customization options. They should be able to work with you to design a membrane filter press that meets your specific requirements.

Technical Support: The manufacturer should offer technical support to help you with any issues you may encounter with your membrane filter press. They should have knowledgeable staff who can answer your questions and provide guidance on maintenance and troubleshooting.

Price: Price should not be the only consideration, but it’s important to choose a manufacturer that offers competitive pricing for their products. You should compare prices from different manufacturers and consider the overall value of the product.

Customer Reviews: Check customer reviews and testimonials to get an idea of the manufacturer’s reputation and the quality of their products and services.

By considering these factors, you can choose the right membrane filter press manufacturer to meet your filtration needs.

About membrane filter press Systems

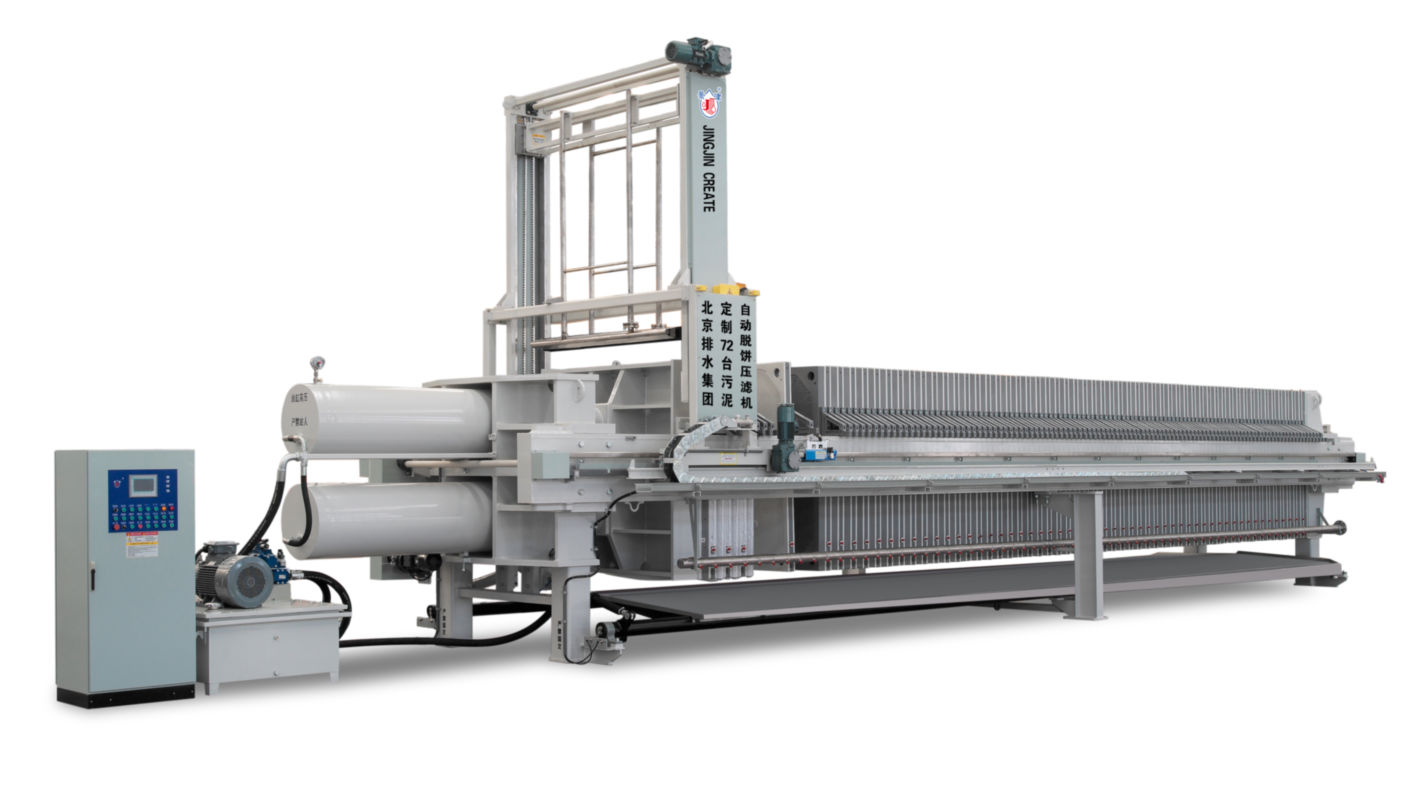

A membrane filter press system is a type of filter press that uses a membrane filter to separate solids and liquids in a solution. The membrane filter is a thin, flexible material that is placed over the filter plates in the press. When pressure is applied, membrane filter press the membrane filter expands, creating a seal between the filter plates and the filter cloth. This seal allows the pressure to build up and forces the liquid through the filter cloth and into the collection chamber, leaving the solids behind.

Membrane filter press systems are commonly used in industrial and municipal applications, including wastewater treatment, mining, chemical processing, and food and beverage processing. They are often used to remove impurities and solids from liquids, to concentrate or clarify solutions, and to separate different components in a solution.

There are two types of membrane filter press systems: recessed plate and diaphragm squeeze. In a recessed plate system, the membrane is fixed to the filter plate and expands when pressure is applied. In a diaphragm squeeze system, the membrane is attached to a flexible diaphragm, which expands when pressure is applied. Both types of systems can be automated and customized to meet specific filtration needs.

Membrane filter press systems offer several advantages over other filtration methods, including high efficiency, low operating costs, and easy maintenance. They can be used to filter a wide range of solutions, from high-viscosity fluids to corrosive chemicals, and they are ideal for applications that require precise separation and high-quality filtration.